R&D

Since its establishment in 2001, ALUS has consistently leaped forward as a leading aluminum mobility material/component company through continuous research and technological development.

ALUS has been actively engaged in the development of prototypes for BPC (Battery Pack Case) for domestic primary car manufacturers in the field of mobility materials/components. Additionally, the company has collaborated with automotive research laboratories, conducting activities such as extrusion mold simulation, pre-production trials, and alloy material research.

Battery Pack Case

Projects

Total Number of Parts

Items

Total Number of Dies

Dies

Alloy Design & Mechanical Properties

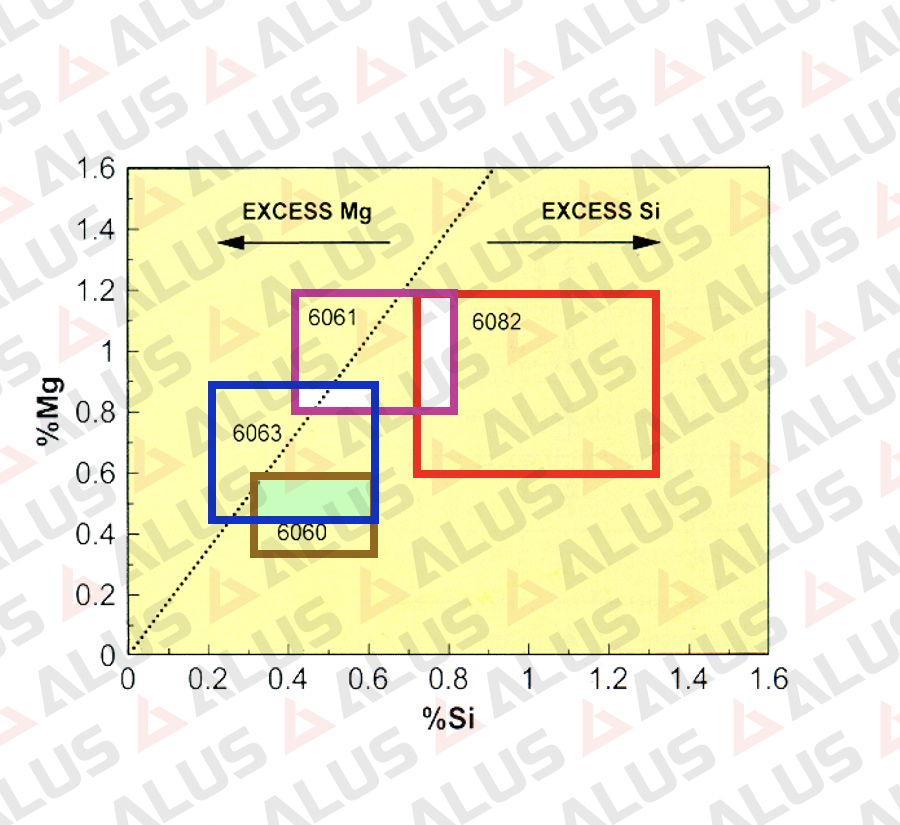

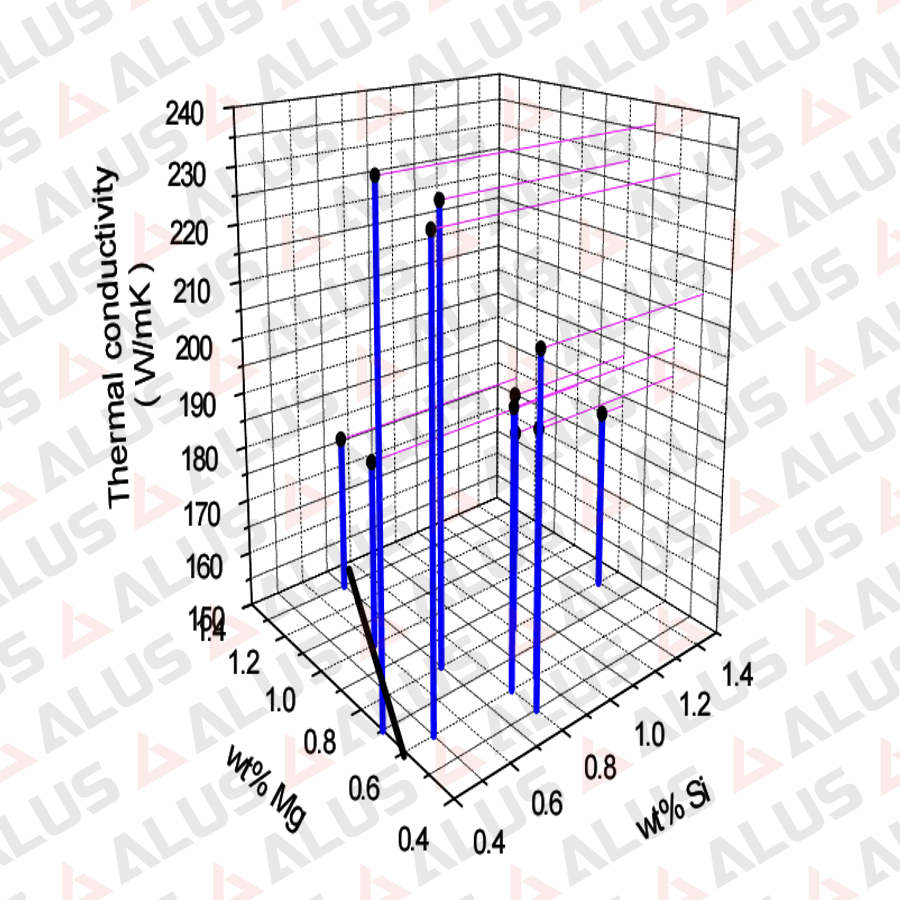

ALUS develop the alloy design for 6XXXX series high-strength materials through data analysis as follows. Alus has achieved the requirements of automotive clients by analyzing material characteristics based on variations in Mg and Si content, which are key alloy components.

The influence of addition elements in A6XXX alloy.

Mg, Si addition ranges for A6XXX alloy (Al-Mg-Si)

Changes in mechanical properties according to variations in Mg and Si content

Changes in thermal conductivity according to the main components

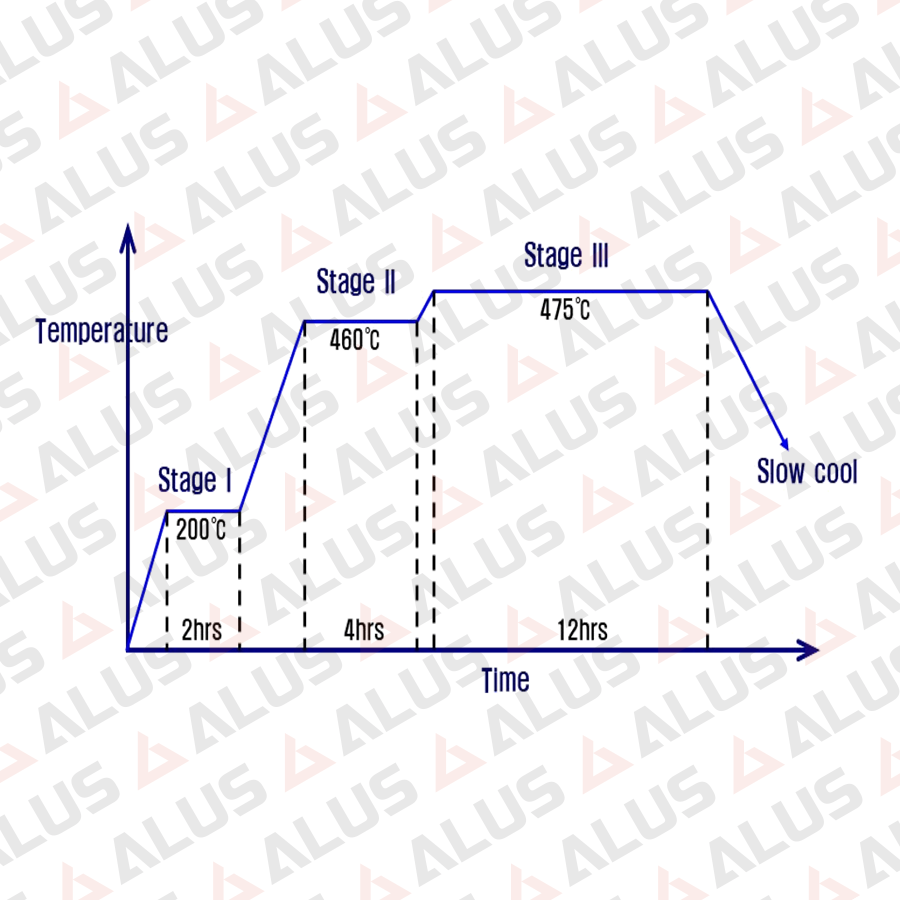

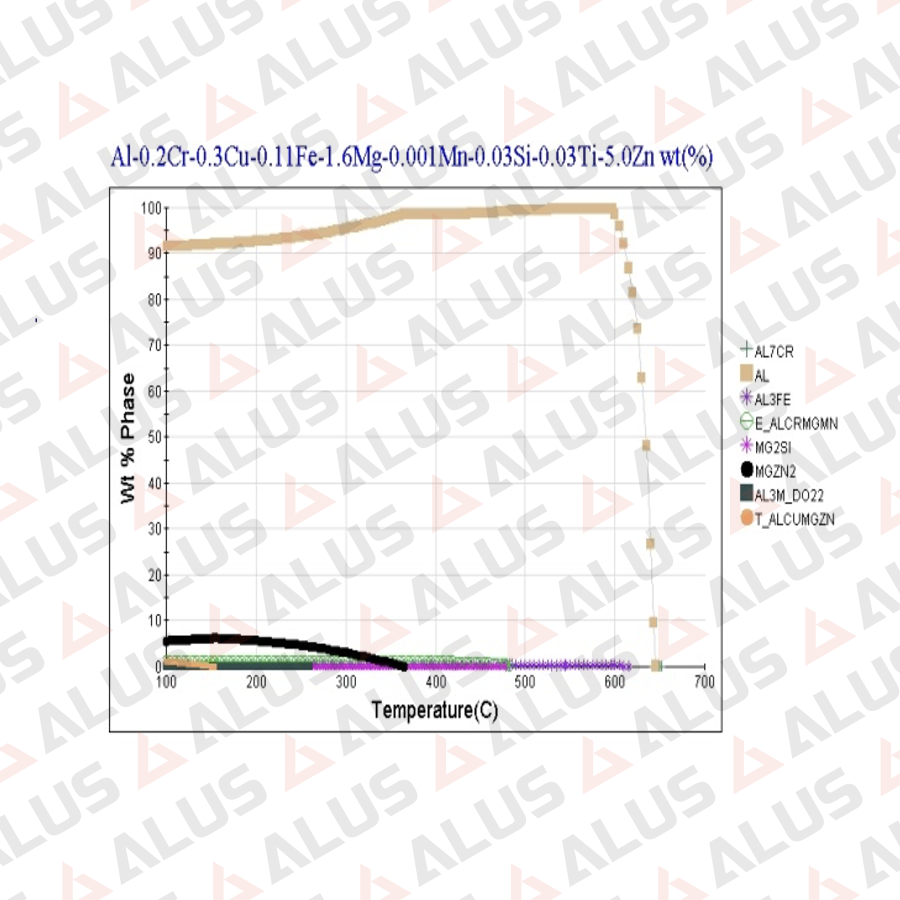

We develop the alloy design of 7XXX series materials through the following data analysis. ALUS has secured technology to improve the formability of extrusion based on the content of key alloy elements Zn, Mg, and Cu, increasing the productivity of bumper and seat rail extrusions by over 10%.

Extrusion characteristics based on the content of key elements in A7XXX alloy.

Heat treatment technology for A7XXX series alloys (billet homogenization).

Solidus temperature and phase transformation according to changes in alloy composition.

Die Design & Simulation

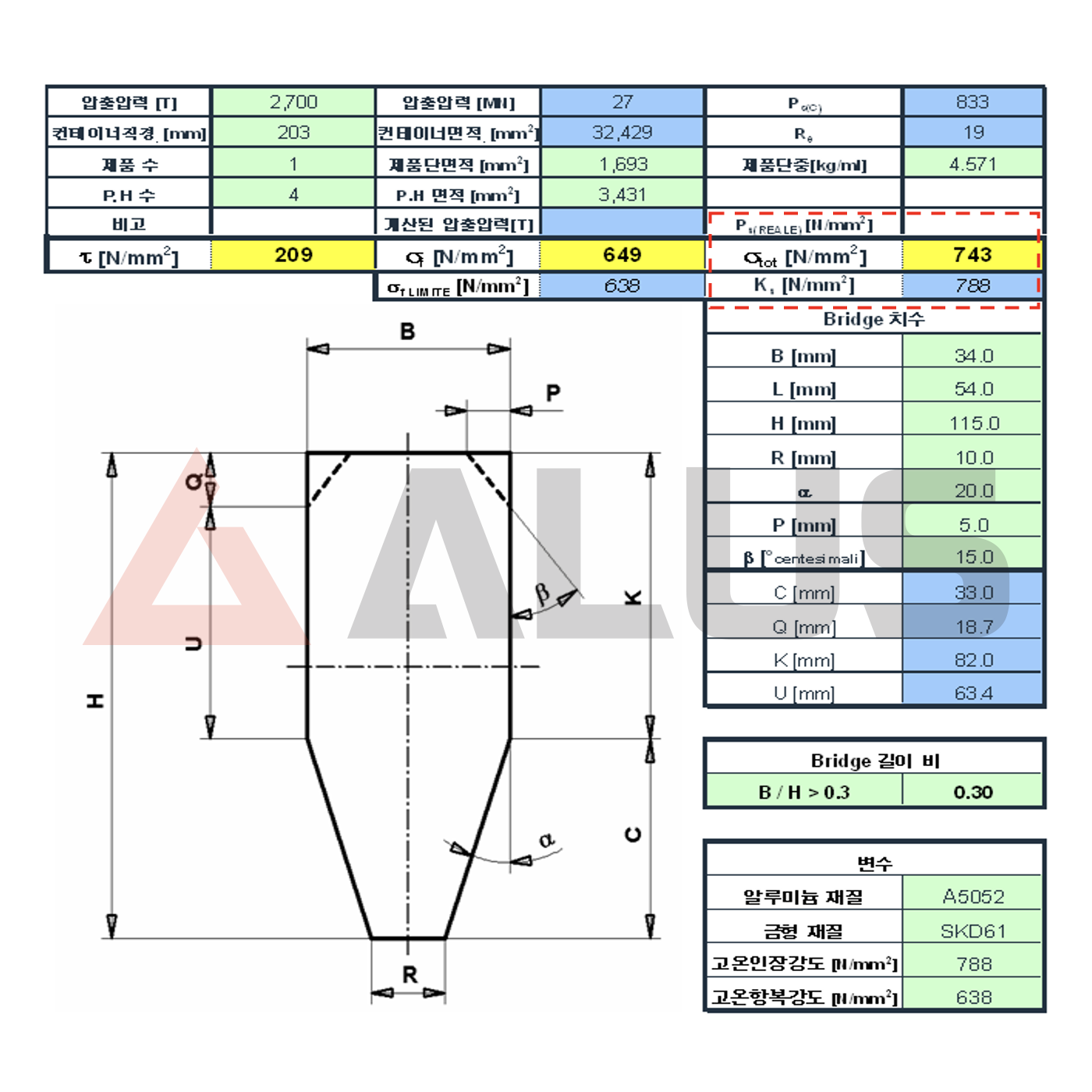

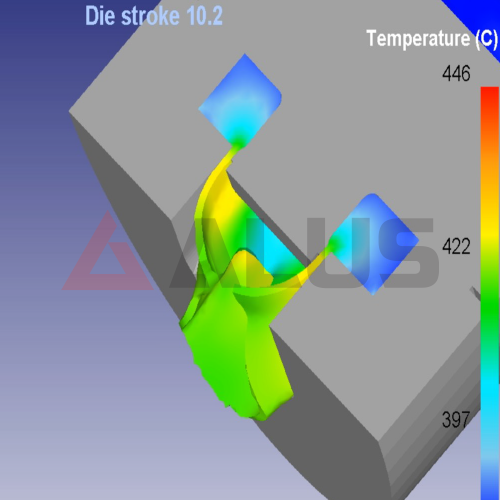

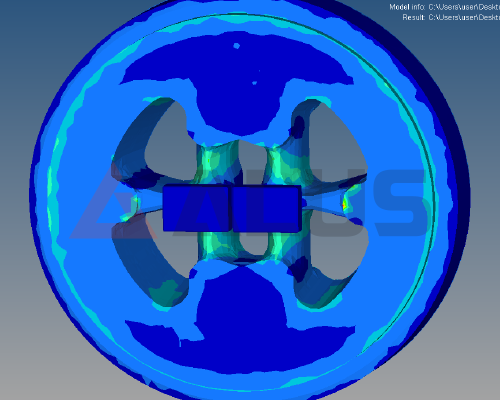

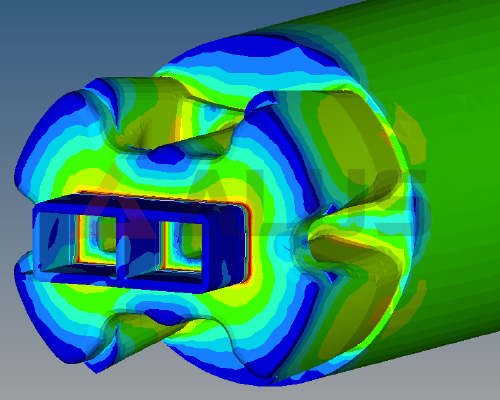

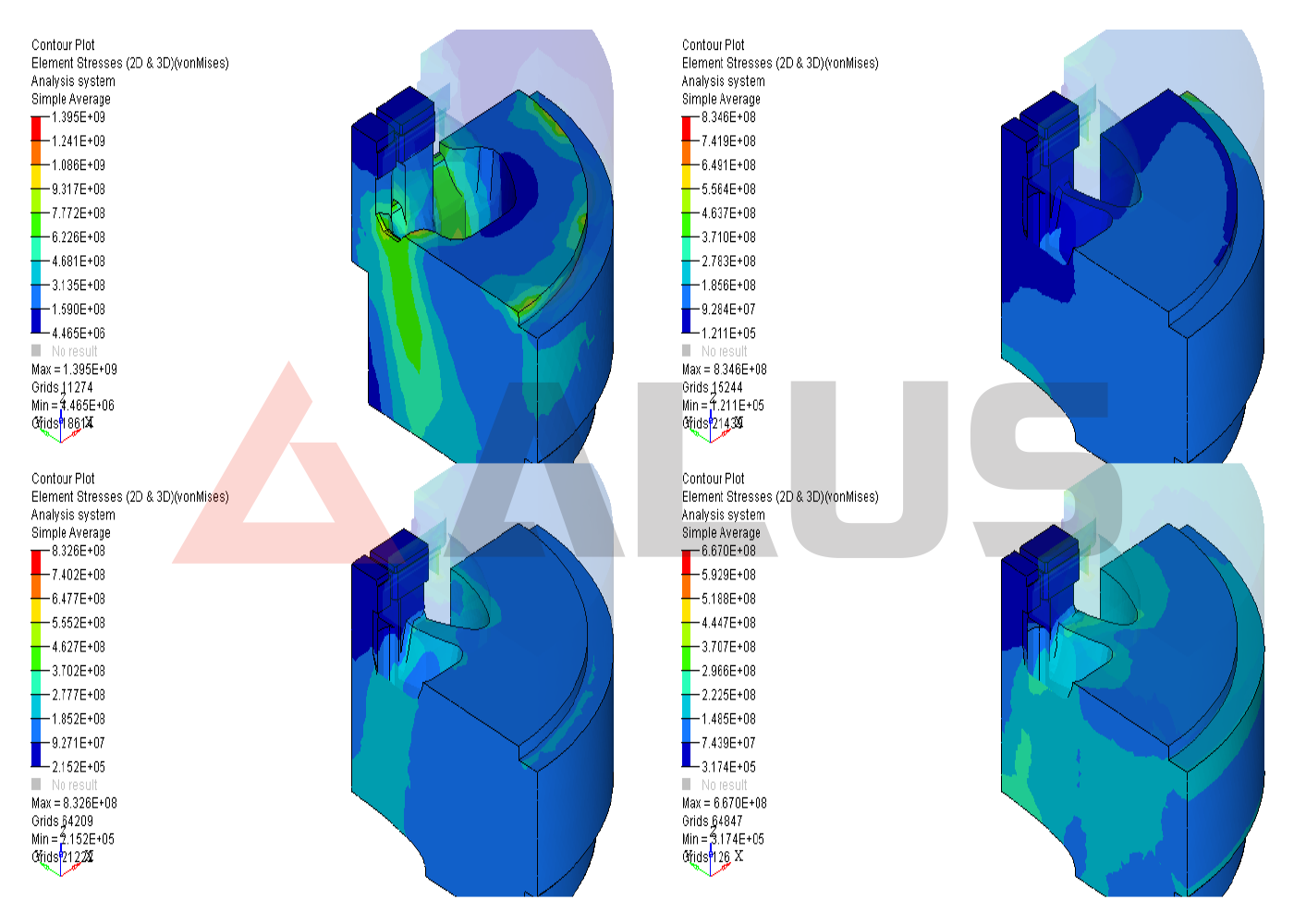

ALUS conducts mold design analysis and simulation for productivity enhancement through mold fracture prevention and consistent metal flow control, as follows.

Theoretical calculation of added loads to the mold for fracture prevention

Deformation caused by Metal Flow Difference by Extrusion Material Location

Stabilization of Metal Flow due to Bearing Length Modification

Mold Loading Pressure

Product stress

Exit temperature

DIE Stress(MPa)

출구온도

ALUS is enhancing its technological capabilities through continuous R&D and collaboration with various institutions and partner companies.

R&D Project

Lead Agency : Ministry of Trade, Industry and Energy

Managing Organization : Korea Energy Technology Evaluation and Planning

Total Project Cost : KRW 2,387,000,000

Lead Agency : Ministry of Trade, Industry and Energy

Managing Organization : Korea Institute for Advancement of Technology

Total Project Cost : KRW 477,000,000

Project Period : May 2023 to April 2024

Lead Agency : Korea Institute for Advancement of Technology

Total Project Cost : KRW 400,000,000

Lead Agency : Ministry of SMEs and Startups

Management Agency : Korea Technology and Information Promotion Agency for SMEs

Total Project Cost : KRW 309,926,000

Non-R&D Project

Supervising Ministry: Ministry of Science and ICT

Managing Organization: R&D Special Zone Promotion Foundation

Total Project Cost: 50,000 million won

Supervising Ministry : Smart Manufacturing Innovation Promotion Team

Managing Organization : Chungbuk Techno Park

Total Project Cost : 145,750 million won

Supervising Ministry : Smart Manufacturing Innovation Promotion Team

Managing Organization : Chungbuk Techno Park

Total Project Cost : 70,000 million won